The Definitive Guide to Sheroz Earthworks

The Definitive Guide to Sheroz Earthworks

Blog Article

Not known Factual Statements About Sheroz Earthworks

Table of ContentsThe Best Guide To Sheroz EarthworksThe Facts About Sheroz Earthworks UncoveredThe Greatest Guide To Sheroz EarthworksSome Known Details About Sheroz Earthworks

There are a number of firms that produce quality equipment control systems, and Trimble maker control is among the industry leaders. We can produce 3D declare equipment using Trimble equipment control systems as well as Topcon, AGTEK and all other significant machine control systems. fj dynamics autosteer review. Commonly, our turnaround time is concerning 5 days, depending upon the intricacy and dimension of your taskJust head to the Device Control tab or the Send United States Job (https://www.video-bookmark.com/bookmark/6399293/sheroz-earthworks/) tab on our site and send your project

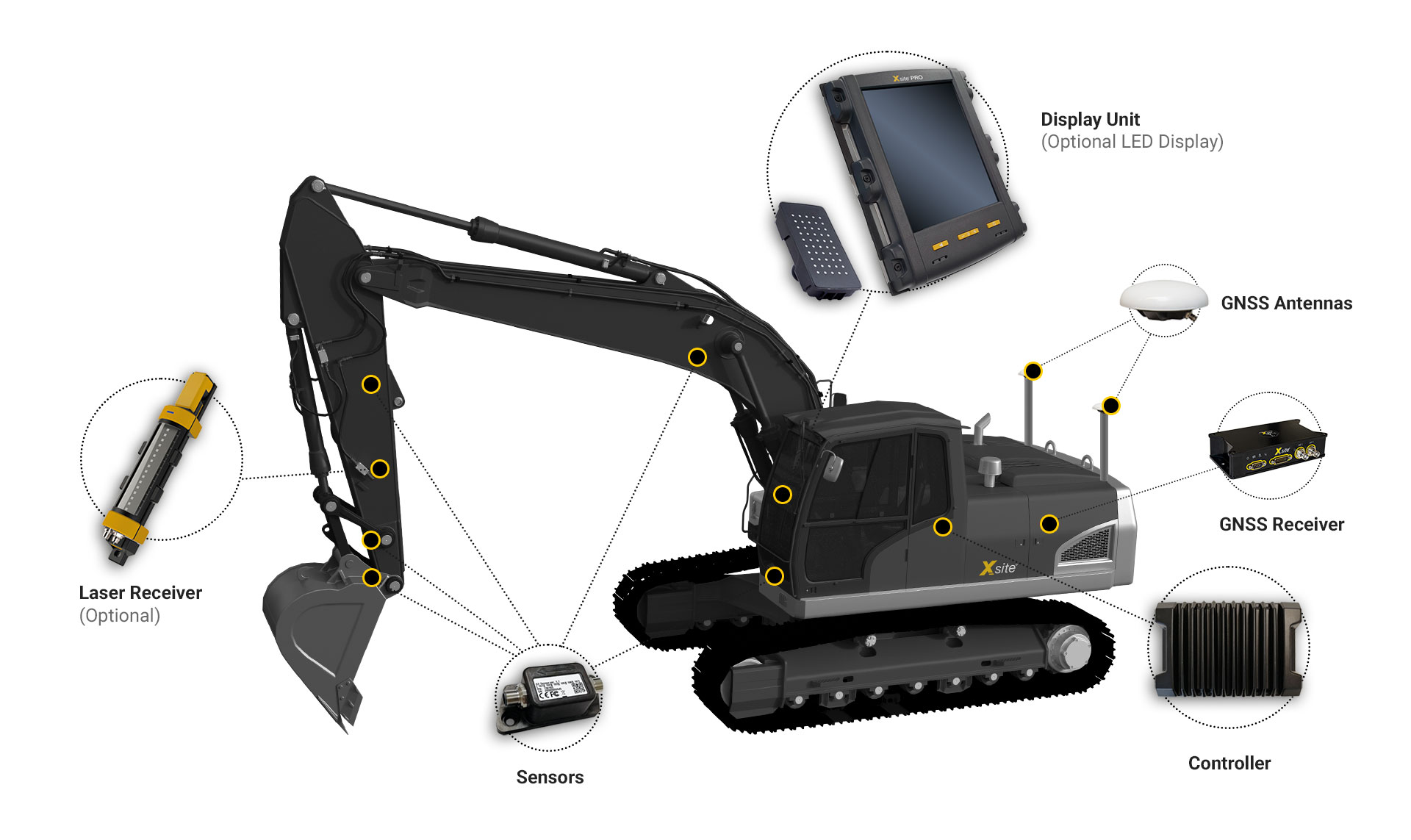

With the aid of the device control system the operator will find it very easy to tackle any type of job. The clear 8,4 touch display with intutive interface enables the driver to conveniently keep an eye on the difference in the elevation of the bucket's blade and the target surface. Different features of the Xsite PRO 3D are made as easy to utilize as possible.

With the current tech boom taking the globe by storm, the construction sector has actually gone through numerous adjustments and improvements in recent times. One of the tech developments leading this revolution is machine control innovation - topcon gps. Maker control technology, which has been spreading out almost everywhere, includes using satellites and 3D versions that make it possible to evaluate a machine's specific area on earth and compare this position with a wanted design surface area

Excitement About Sheroz Earthworks

Throughout a building and construction task, there are numerous times when people need to make important decisions to make certain that points remain on track in terms of time, efficiency, and budgetary aspects. With maker control innovation, you can make vital decisions based on concrete data instead of fallible standard methods or varying driver abilities and experience.

Countless 3D GPS positioning providers have actually confirmed over and over again that carrying out device control technology will certainly help bring your operating expenses down by boosting performance on your task websites. Yet, how does this fantastic technology make that viable? The following are a few of the major manner ins which maker control innovation boosts job website performance: It can be extremely frustrating (and expensive) to deal with extensive downtime since you have to execute a rework.

Furthermore, fewer reworks will result in more efficient task conclusion and faster turn-around times. One more method that maker control technology can help enhance efficiency is by enhancing the predictability of various jobs when it concerns factors such as required time and products. https://www.domestika.org/en/floydoverbeck4500. When you can anticipate such elements, it is possible to assign tools and employees, and it is also much a lot more feasible to maintain material costs to a minimum

The Ultimate Guide To Sheroz Earthworks

On the other hand, if you are unable to precisely assess how to assign time, products, and workers for projects, it could cause you having to invest added time and sources to fix miscalculations. Along with working more effectively, maker control technology allows you to work smarter. This innovation can educate a specialist to reduce down their use of three dozers on a certain work website to simply two, freeing up the third to one more job website.

Many service providers established apart a considerable amount of time and money for a job to dedicate to re-staking throughout the work for numerous reasons, such as changing layouts or risks obtaining moved or run over. With device control modern technology, the data points remain the same unless the design modifications, so you do not have to worry about dealing with this.

Equipment control innovation makes it easier for unskilled employees to handle their deal with building and construction work sites. Given that there is less room for errors, there is less of a learning curve for brand-new employees. It will certainly likewise be much easier to draw in the interest of new, younger workers, hence improving hiring periods.

The ideal way to ensure you can take full advantage of the positive impact on your service is to select a GPS champion who can function directly with the technology provider. We think all companies deserve the possibility to try brand-new innovation, so we developed an 18 month Rent-To-Own program that permits you to understand the financial advantages of the system while you pay for it.

They are specialists on Hemisphere GradeMetrix, Topcon, and Trimble systems. Whether you need assist with installation, calibration, documents management, or driver user interface training, we would certainly be pleased to provide remote or onsite assistance and walk you through easy-to-follow options. Our ultimate objective is to make implementing 3D technology right into your organization very easy and painless.

For short-term tools leasings, or if you do not intend to buy devices, we provide reasonable and versatile leasing choices. Our heavy devices professionals would certainly likewise rejoice to assist direct you in the right instructions regarding such issues. To find out more regarding our excavators up for sale or to learn more regarding the device control innovation we offer, call Terrific West Equipment at 1-833-730-0613 or contact us here.

Report this page